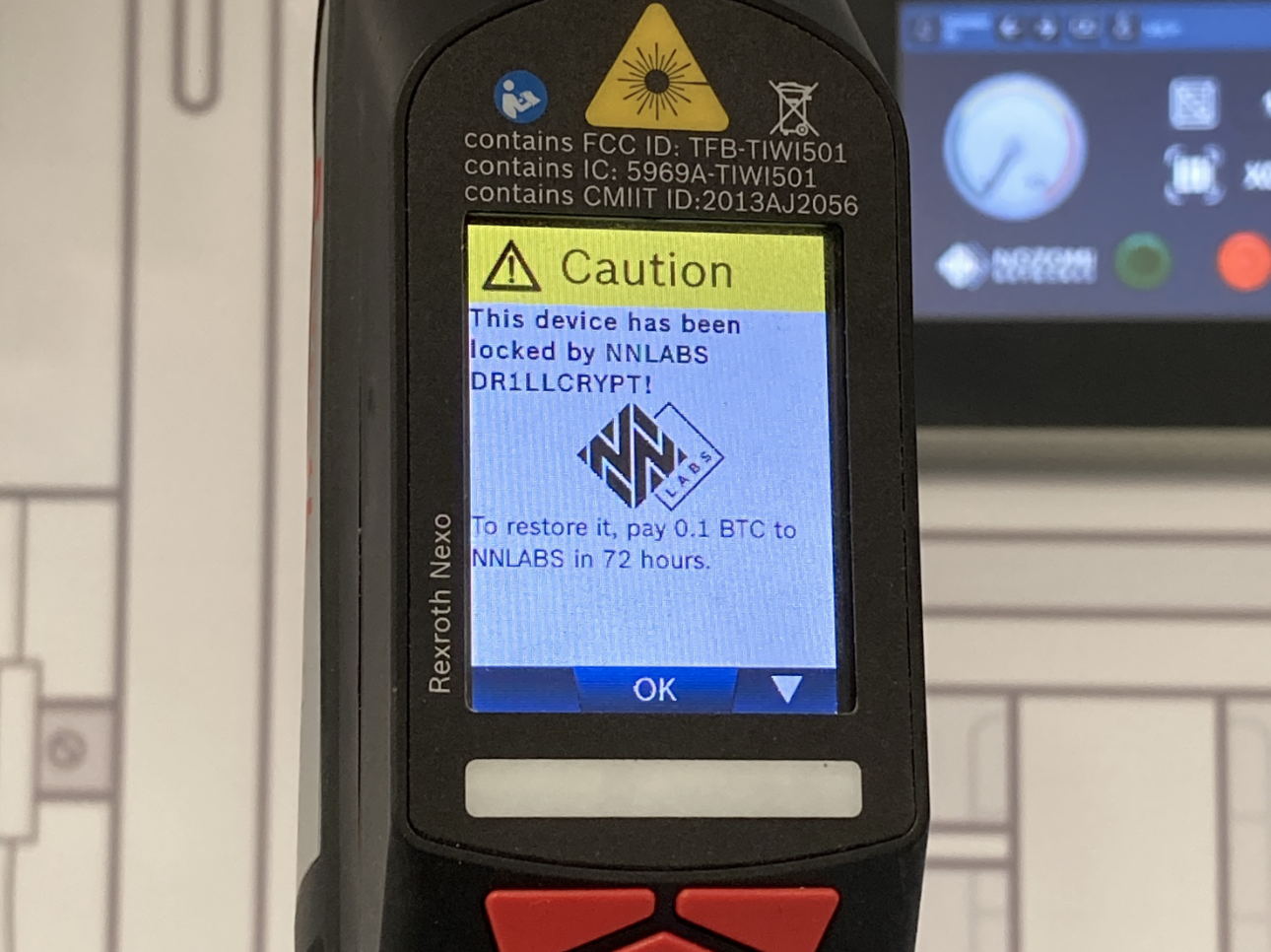

Why put ransomeware on a wrench?

For leverage

Pay us in 3 days or we’ll disable it. This is not a drill.

Ba-dum tss!

LOL.

I think I am less concerned about the ransomware and more confused as to why there is a wrench that can connect to the internet. What use would that provide to the user that would improve it?

Quality assurance on production lines, so there is a record of what happened.

A few ideas off the top of my head

- asset tracking

- location awareness

- ability to send out mass specs to devices

- device assignment

- tracking working hours

I’m not saying all of these are good ideas, or that they couldn’t just have a centralized hub that just pushes and pulls this information. That said, the website for them does list that they also have a camera for scanning barcodes. I could see having barcodes linked with a certain torque spec and that requiring a network connection if the information wasn’t hard coded. website

The wrench is to tighten bolts to spec. You can program it to tighten different bolts to different tightness and that can be programmed online.

That’s the neat part, there isn’t. There is, however, significant incentive to the tool’s manufacturer. Who can, I’m sure, not only demand a subscription for continued use of the tools but also employ lucrative maintenance contracts and other sundry corporate nonsense. I can tell you from a brief stint in the industrial automation industry that the sale of the equipment is not the money maker; it’s the ongoing service contract on it.

If these are meant to be used by hand I see no reason they can’t just be configured on the tool itself and not need an internet connection. And if the point is plantwide automation, these sit directly in the bottom of the ugly trench between tasks that must be done by a human for whatever reason on one side, and just being done by a damn robot to begin with on the other.

And a further clarification: Even if there is a use case for a hand tool being networked, having it connected to the outside internet is just bonkers.

I see no reason they can’t just be configured on the tool itself and not need a network connection.

Say you’ve got a couple dozen of these wrenches and during retooling new specs come out. You can either pay a group of people to go around and upload all the new specs to the tool or push it from a central server to all the tools.

Boeing Boeing Boeing Boeing…

-

Hey Joe, is this set up for the correct specs for the plug doors?

-

Bert, don’t ask such things, else we’ll be here until night. Just fix those darn bolts with it, then let’s go for a drink.

-

You can either pay a group of people

So, like, the guys who are holding the wrenches all day to begin with?

Even so, none of the examples anyone has come up with in this thread have required having the friggin’ things connected to the internet. That’s our beef here. Not necessarily networking capability.

In fact, back when I was in automation (in the dark ages of ~2008) it was already considered unthinkable not to air-gap all of your mission critical production equipment. A ton of that stuff was networked, sure (and you’d shit a brick if you saw how much of it is still interconnected with RS-485 serial…) but not exposed to the outside world in any capacity. Nor would anyone want it to be, for obvious not-getting-pwned reasons.

I am not a fan of making everything part of ‘the internet of things’

This feels like one of those things that’ll go exactly opposite of what I expect. Ten years from now I’m be explaining to my grandkids how much harder live was before wrenches were Internet connected.

I can’t imagine a single valid reason to have an Internet connected wrench. But life is weird, so I’m guessing I’ll keep one synced to my fax machine someday.

Do we need this news posted 50 times over the course of a day?

Honestly is the first one I see with s picture showing the ransom request.

Repost…

https://lemmy.ca/post/12959993