“This breakthrough development translates into a remarkable improvement in cell-core energy density, reaching 2,000Wh/L in batteries and approximately 1,700Wh/L in full-size EV batteries – more than double the performance of current state-of-the-art technologies,”

“Sienza’s 3D pure silicon anode has demonstrated an average gravimetric capacity of 2,941 mAh/g,” Professor Gharib said. “This means that for every gram of silicon, our batteries can store 2,941 milliampere-hours of electricity, significantly higher than the industry standard for graphite, with a gravimetric capacity of 372 mAh/g.”

Aside from completely avoiding the cobalt issue, Sienza notes that its manufacturing process does not rely on the solvent-based coating systems deployed for producing conventional lithium-ion batteries. Sienza cites one commonly used solvent in particular, N-methyl-pyrrolidone (NMP).

That sounds really impressive. But describing it as “the best thing ever” really has my skepticism at full mast.

ETA: I can’t find any mention of a single drawback or tradeoff to this new technology. That makes this a marketing piece rather than journalism. Nothing is ever better in every conceivable way than the current state of the art.

Probabilistically, sure, but it’s not impossible that there has been some piece of knowledge or understanding that’s been missing, and that massive breakthroughs are possible once the process is figured out.

I think a fair modern example is LED light bulbs. They are better in every conceivable way than incandescent or fluorescent lightbulbs: they last longer, use less energy, shine brighter, use less toxic materials, and are easy to mass produce. But there were several decades where much of the industry believed that LEDs would never be very useful as a light source because we could only produce red and green, and it was generally believed that a blue LED would be impossible to produce.

Then one guy decided it would be his life mission to invent the blue LED, and the sonuvabitch did it. Now LEDs are the only sensible thing to use to produce light.

It’s always possible for this kind of breakthrough to happen, especially in material science where the complexity of how molecules interplay is nearly incomprehensible.

LEDs are worse at color accuracy (CRI) which is hardly relevant unless you need it, but it’s just to show that even they aren’t strictly better than what they replace

CRI is defined as how closely a light source matches the spectral emission of a thing glowing at a specific temperature. So, for a light source with a 4000 k color temperature its CRI describes how closely its emission matches that of an object that’s been heated to 4000 k.

Because incandescent bulbs emit light by heating a filament by definition they will have 100 CRI and its impossible to get any better than that. But the emission curve of incandescent lights doesn’t actually resemble that of sunlight at all (sorry for the reddit link). The sun is much hotter than any incandescent bulb and it’s light is filtered by our atmosphere, resulting in a much flatter more gently sloping emission curve vs the incandescent curve which is extremely lopsided towards the red.

As you can see in the above link, there are certain high end LED bulbs that do a much better job replicating noon day sunlight than incandescents. And that flatter emissions profile probably provides better color rendering (in terms of being able to distinguish one color from another) than the incandescent ramp.

Now, whether or not you want your bulbs to look like the noon day sun is another matter. Maybe you don’t want to disrupt your sleep schedule and you’d much rather their emissions resemble the sunset or a campfire (though in that case many halogen and high output incandescent lamps don’t do a great job either). Or maybe you’re trying to treat seasonal depression and extra sunlight is exactly what you want. But in any case I think CRI isn’t a very useful unit (another reddit link).

I find this info interesting, especially the fact that incandescent bulbs do not replicate sunlight. At the same time, I was also trying to keep things simple as just a minute counter point. But I guess I was wrong anyway, and that led bulbs are better in every way than incandescent bulbs then.

You can buy high (97-99) CRI LEDs for things like the film industry, where it really does matter. They are very expensive, but can pay for themselves with longer service life, and lower power draw for long term installations.

The CRI on regular LED bulbs was climbing for a long time, but it seems as though 90ish is “good enough” most of the time.

And early LEDs had flickering issues w/ dimmers. And somehow they’re still way more expensive than incandescent bulbs (not sure about per hour of use, but certainly by unit, which matters when renting).

A breaktrough would be needed to electrify ship and flight. Would be great if it is that.

Electrify ship you say?

We’ve seen so many battery breakthroughs in academia in the past decade, it’s about time some of them start to transition into production.

For ships they are rediscoverings sails so that might be enough

Possibly difficult to mass produce. That’s usually what kills all the new great battery tech.

I hope this encourages some manufacturers to endorse it and bring it to market. That could make them save and profit a lot compared to other battery tech manufacturers.

Even if this gets relegated to niche applications, all improvements are good improvements.

At the very least, it demonstrates that certain targets are possible, and that’s sometimes necessary to secure funding to find those cheaper/scalable options.

I’m doing a PhD in batteries. Not this issue specifically, but I hear a lot about different battery fields so I think I can speak on it.

The drawback is that the anode expands and contracts a lot during a cycle. This puts a lot of strain on the binder holding the film together, and on the contact between the film and the aluminum foil. This makes the battery degrade and fail after fewer cycles.

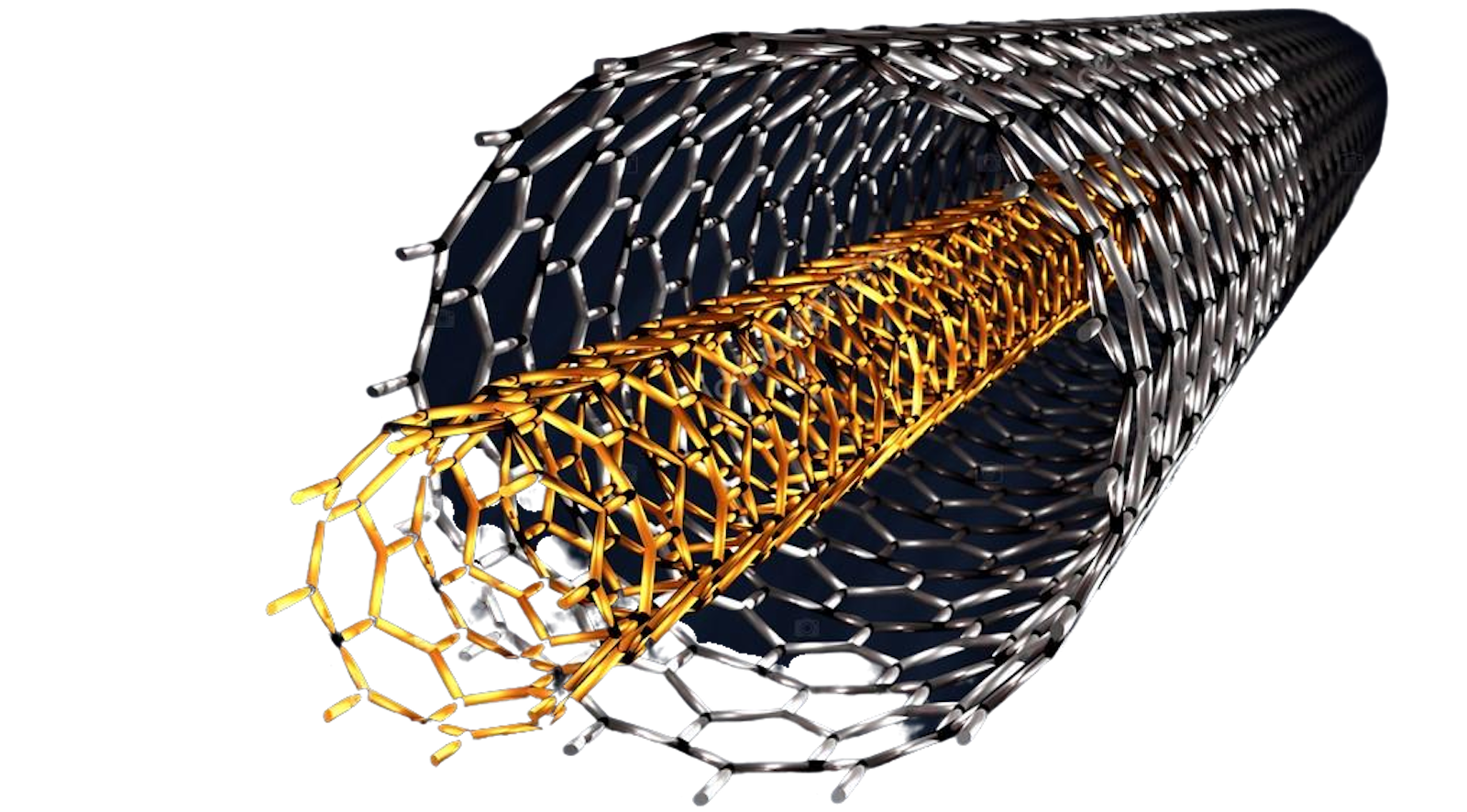

Below is an article in nature from 2020 where a group is trying to solve this issue by coating the Si platelet particles with carbon (adding complexity and mass). You can read about this issue on greater detail in the abstract and introduction. There are many articles tackling the same issue (many cited in this article), I just picked this one because it had info in the intro/abstract. Stable high-capacity and high-rate silicon-based lithium battery anodes upon two-dimensional covalent encapsulation

In addition, the expansion/contraction cycles causes the electrolyte to dry up. During the first few cycles of any battery, the electrolyte reacts with the electrodes to form passivating layers on the electrodes. When the particle contracts/expands excessively, the particle breaks apart and the passivating layer is ripped up. The passivating layer is then reformed, now on a larger area, which consumes more electrolyte. Eventually the cell fails from the lack of electrolyte.

Below is an article in nature from 2024 where a group tries to solve this issue by designing an electrolyte that creates a passivating layer that keeps its shape when the particle contracts, creating a shell. You can read more about the issue In the abstract, intro, and figures. High voltage electrolytes for lithium-ion batteries with micro-sized silicon anodes

These are solvable issues, but a lot of the solutions are either too complicated to scale up, or add too much mass/volume to make it worth it, or slow down the discharge rate. And any change anywhere, needs to be taken into account on the rest of the parts of the battery.

I don’t know what Sienza Energy did. It’s an MIT spin-off, so they probably know their stuff. All issues don’t need to be solved for a battery to be functional, it just needs to be good enough. Any new battery factory “just” needs to find and scale-up the state-of-the-art components in the right combination. There will be a ton of drawbacks, but it will be better than the last battery factory.

I appreciate the information and the links. I didn’t mean to imply this isn’t exciting or useful technology, just that when an article is pure hype I come away thinking someone is trying to sell me something, not give me actual information.

I feel the same way when I read these articles. They make it seem like everything is an earth shattering breakthrough when in reality, they’re making a small (albeit worthwhile) contribution towards solving a problem that already has 20 other solutions with other trade-offs.

But I like it when I read about any new battery tech being scaled up do industrial scale, like the article here. That’s the hard part.

Any expert opinion on this idea? https://spectrum.ieee.org/flow-battery-2666672335

I don’t see the point of nanoelectrofuel flow batteries. I’m sure there are niche applications that I can’t see. But not anywhere near what that author is describing.

Flow batteries are good because they’re so cheap per mAh and W, and if you’re using them for grid scale storage, size and weight doesn’t matter. The energy density is greatly increased when you add nanoparticles, to the point where it competes with EV batteries. This includes the extra weight of pumps and membranes. I think the addition of pumps and membranes make it really unfit for personal vehicles, even if it increases the energy density. The article talks about military applications, but doesn’t really explain what it could do better that Li-ion except for fire safety. And they’d be dependent on the fuel of this one company.

I think its major selling point is that it’s cheap and very modular, so you can easily choose what capacity/power your grid scale facility should store/output, and change it after the fact. But if your building a facility, then the weight doesn’t matter as much and you might as well skip the nanoparticles.

As a technology I think it’s really clever. It’s not a very well studied idea. They’re tight lipped and I assumed it was some sort of Vanadium flow battery, but judging by the articles they’re citing in their patent and their conference talk abstract I’d speculate the cathode nanoelectrofuel is a water based slurry with lithium iron phosphate nanoparticles and carbon powder. The particles discharge like they would in a conventional Li-ion battery. But then instead of charging them you pump the slurry to your big tank, replacing them with charged particles. You need the carbon to conduct the electrons from the suspended particles to the current collector plate.

Thank you for that additional info. I’m highly intrigued with this because vehicles would “refuel” in a familiar way, and there could be a choice to also plugin recharge if someone had their own facilities, at home or work.

It might be the bridge needed to entice more conversions, and might improve with experience and time, much as ICE have done since the Model T.