I needed some LEDs so that I could track what my data lines were doing. I started with a bunch of LEDs and resistors on a breadboard.

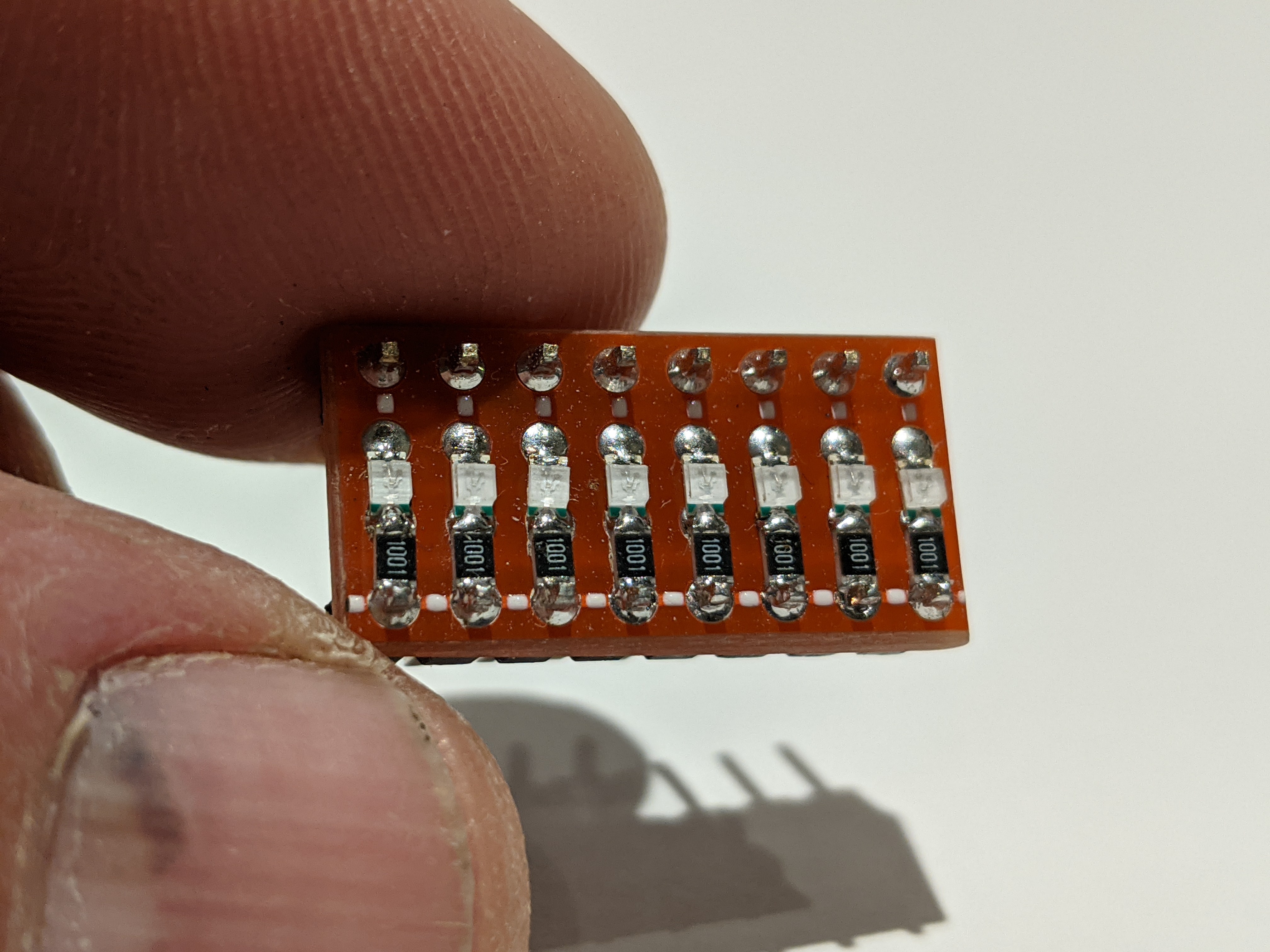

From there I made up a small block of SMD LEDs and resistors on a piece of proto board.

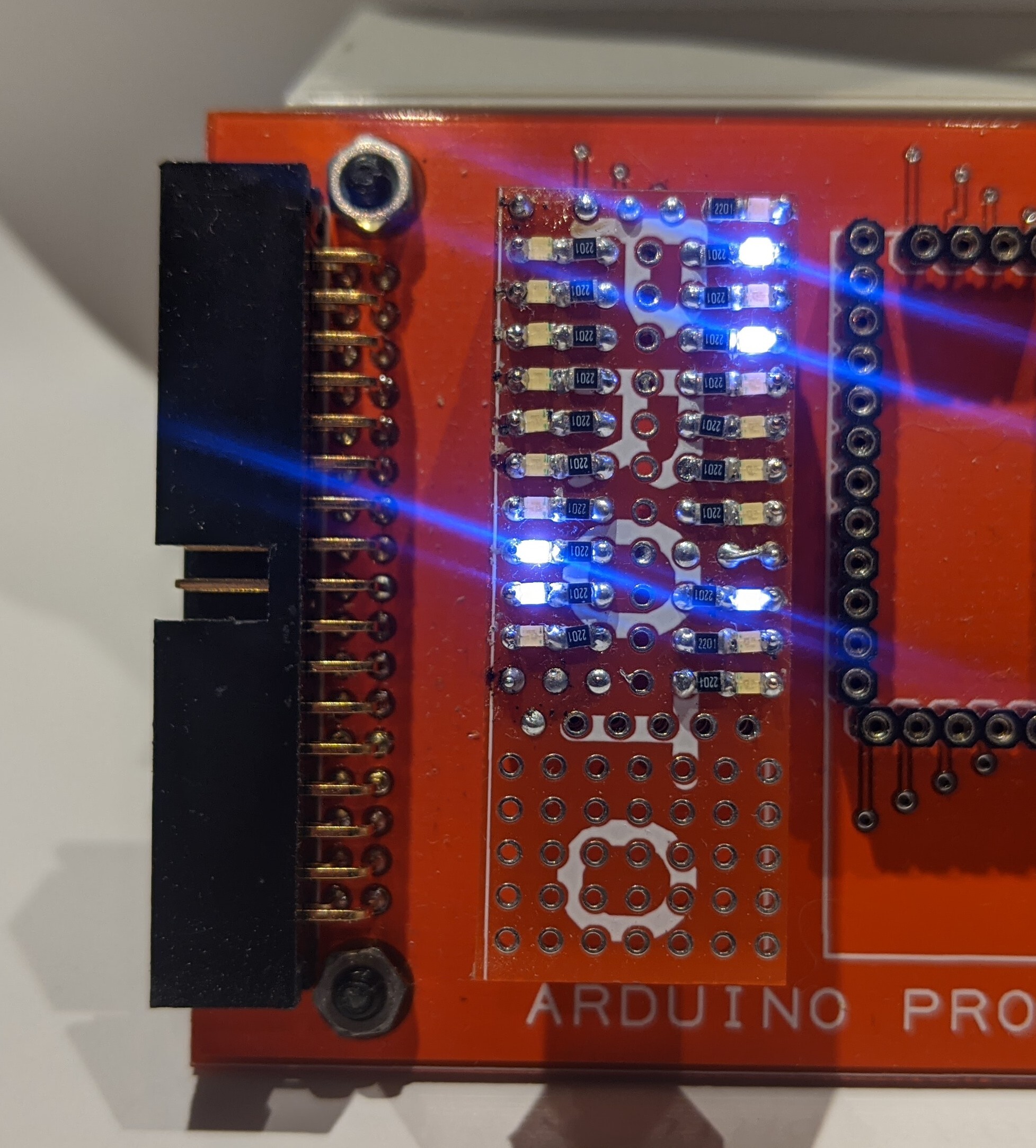

Then I moved to an actual prototype on a dedicated protoboard.

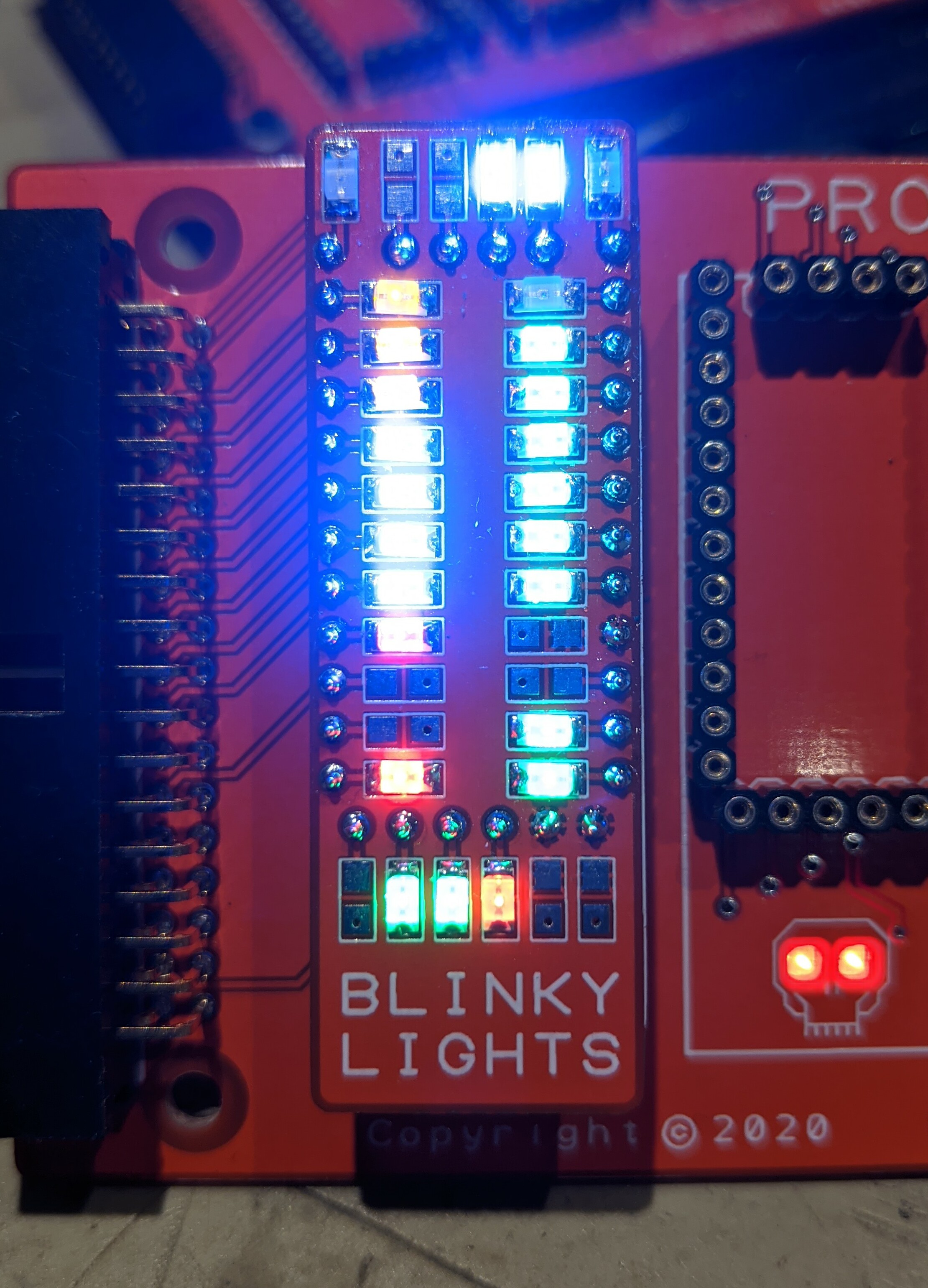

Finally, I produced the finished product. BLINKY LIGHTS!

The friend who I work with can design a board entirely in software, we use Pulsonix, without every making a prototype, send it for manufacture, and get working boards back. Even when I build multiple prototypes I often end up with boards that need FECs to make them work.

Literally wondered about this yesterday

My friend who does most of the design work says I should start with a schematic and parts and then use that to build the board. I need to learn that but I’m an amateur hack when it comes to this stuff and I just brute force the board design. I bought a hobbyist version of Pulsonix so I really should learn how to do it.

I started with the free version of DS PCB. It works very well.

Maybe this year.

Neat